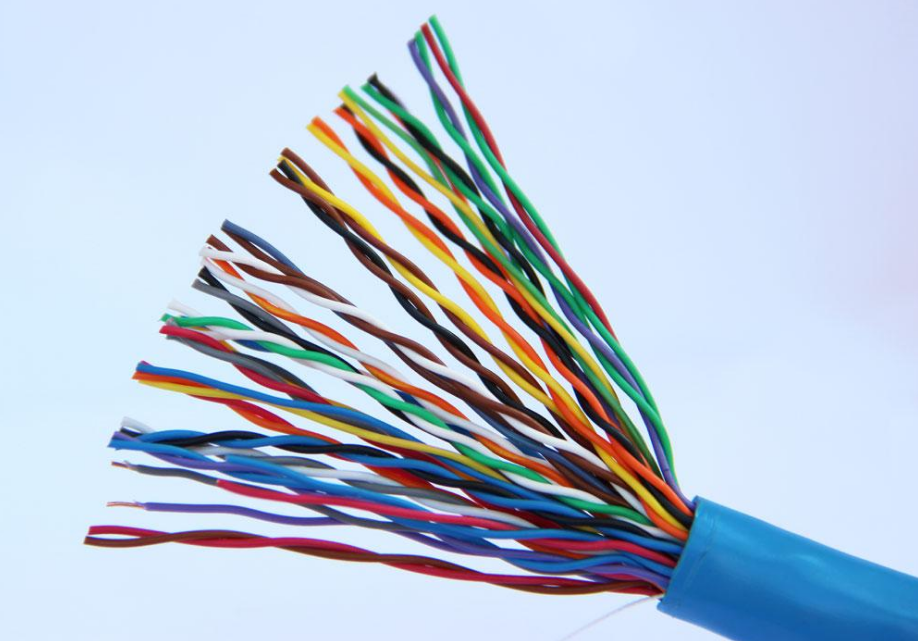

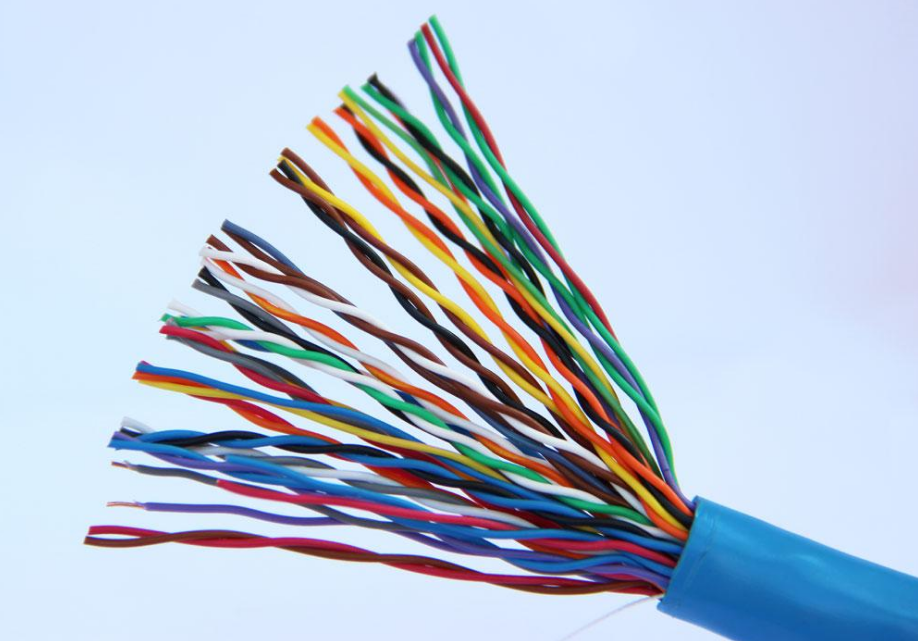

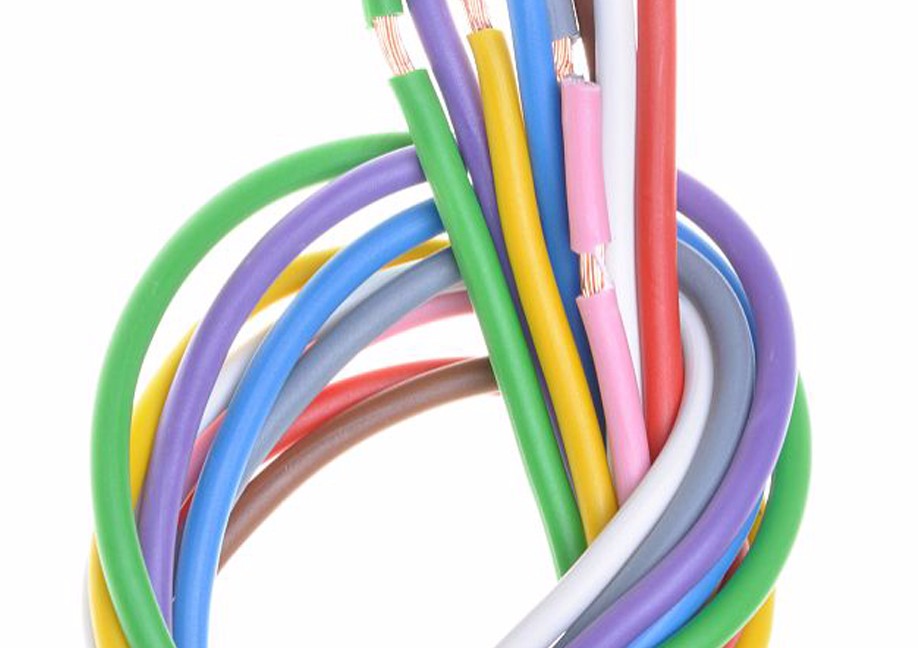

Servo cable series Industry robot wiring harness Industry connector Communication/Downland cable OEM/ODM custom wire harness Industry vision camera cable

Standard flexible shielded cables.Made of 100% PVC/PUR material quality.Stable delivery:7 to 15 work

Detail

Standard flexible shielded cables.Made of 100% PVC/PUR material quality.Stable delivery:7 to 15 work

Detail

High corrosion resistance, the insulation layer has no obvious change after stretching, the outer skin is intact under high p

Detail

High corrosion resistance, the insulation layer has no obvious change after stretching, the outer skin is intact under high p

Detail

High corrosion resistance, the insulation layer has no obvious change after stretching, the outer skin is intact under high p

Detail

High corrosion resistance, the insulation layer has no obvious change after stretching, the outer skin is intact under high p

Detail

Each product before shipment, the QC will check one by one to ensure customer satisfaction

The company has a strong technology research and development team. development team.Product updates faster,according to market demand has introduced new products.

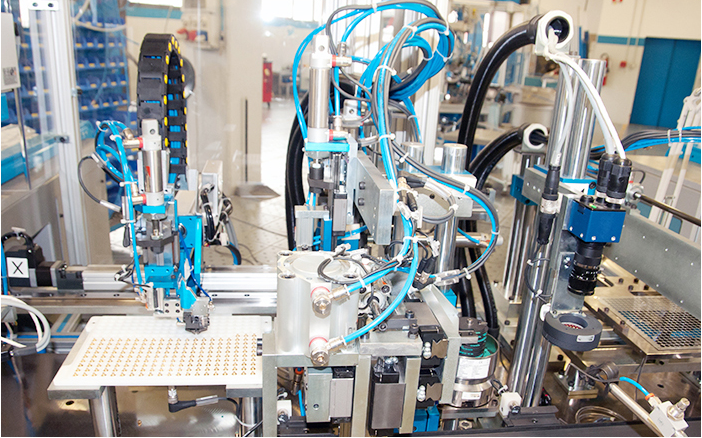

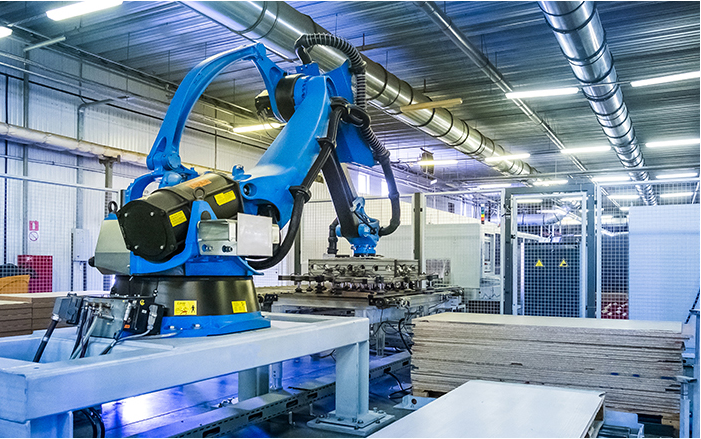

Our company introduced advanced production equipment, improve the product quality, saving the cost of the artificial and productiontime, to provide customers with competitive price

Most of our products through the SGS, ROHS, CE certification, etc

Shenzhen Fulianhui Technology Co., Ltd. Is a company excelling in industrial control products. We specialized in producing customization industrial control cables & selling industrial control products. Our brands cover but not limited to: Mitsubishi, Omron, Siemens, Schneider, Fuji,Fanuc, Yokogawa, Moog,Enidine, Yaskawa, Yuken, Festo, Rexroth, Nidec-Shimpo, AB, Allen-Bradley, SMC, Turck, IFM, Pilz, Banner, Hydac, +F, IPF, Balluff, Honeywell, SKF, Lincoln, Mityvac, Parker, Sick, EMG...

Detail

The use of non-environmental protection cables is strictly prohibited in developed countries, and ou

Detail

The use of non-environmental protection cables is strictly prohibited in developed countries, and our country also attaches g

Detail

Everything in the world has its own attributes and levels. What‘s more, cable products are widely used and have a wide ra

Detail

People in the wire and cable industry know that the process of wire and cable manufacturing requires many processes, but what

Detail

Wires and cables are usually rope-like cables formed by twisting several or several groups of wires. Each group of wires is i

Detail